6YL-68 screw oil press

6YL-68 screw oil press main data

2. Main Specification

(1) Press chamber diameter / length...........................................................................70/200mm

(2) Press screw diameter / length ............................................................................. 68.5/600mm

Press screw speed....................................................................................................137-160rpm

(3) Square rods, quantity / length (Type A, B ).........................................................8/200mm

(4) Clearance between screw shaft and rods .............................................................0.75mm

(5) Prime motor ......................................................................................................... 5.5KW/1440rpm

(6) Sheave diameter.....................................................................................................120-140mm

(7) Dimensions ( L x H x H ) ................................................................................1000 x 538 x 1050mm

(8) Mass............................................................................................................................................140kg

1. Oration principle and structure

1.1 oration principle

When oil presses operating prepared material enters extruding chamber from the hopper and then moves forwards by the rotating pressing screw and is pressed. Under the high-pressure condition in the chamber ,friction between material and screw ,between material and chamber will be created ,which also creates friction and relative movement among material particles. On the other hand, root diameter of the pressing screw caries larger from one end to the other ,hence. When rotating ,it not only pushes particles moving forwards but turns them outwards as well ,meanwhile ,particles adjacent the screw will rotation along with screw’ rotating ,causing every particle inside the chamber to possess different speed. Therefore relative movement among particle creates heat which is necessary during manufacturing because of helping protein change property ,damage colloid ,increase plasticity ,decrease oil’s elasticity ,resulting in high oil productivity.

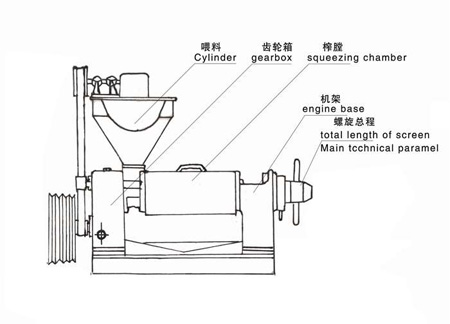

2.Structure: The machine consists of five parts: hopper part, gear box part, press chamber part, screw press part and frame part: see figure (One)

pic(一)

2.Installment

The oil press must be installed by bolts firmly on the foundation and be kept horizontal

3. Lubrication

3.1 Oil press is lubricated by lubricating oil and grease, see table(2)

NO | lubrication | lubricate | Time span | Lubricate replacement period |

1 | Adjusting bolt | Mechanical oil NO.20 | 1-2time/day |

|

2 | Bevel gear | Mechanical oil NO.20 | 1-2time/day |

|

3 | Bearing bush | Mechanical oil NO.20 | 1-2time/day |

|

4 | Gearbox | Mechanical oil NO.20 | Refuel 12kg for the first time | Six months |

5 | bearing | Grease |

| once a year |

4.1.2 After installing the machine, check whether lubricant has been filled in, bolts have been tightened, and handles are operable.4.1.1 12kg of lubricant needs to be filled into the gearbox.4.1 preparations before operating

4.1.3 Check large pulley whether it is loose or blocked, repair it if necessary.

4.1.4 Adjust the tightness of the belt, switch on the motor and check its rotation direction.

4.1.5 Loosen the lock nut and tighten the screw to its end, then loose it for3-4circles and then tighten it again for half circle to assure the gap of the residue cake outlet.

4.2 Operating

4.2.1 Feeding must be steady and slow at the beginning to avoid blocking

4.2.2 In the case no cake is extrude outward,return back the screw for 1-2circle 。If there is still no cake is observed,machine needs to be shut down and checked ,However, in any case, operating the machine backward is absolutely prohibited normally ,cake looks like tile but not sticky ;thickness is 1-2mm ,inner side is smooth ,out side creases and no oil the surface is allowed.

Cake thickness adjustment: Rotating the adjusting handle clockwise will make the cake thicker, otherwise will make it thinner. Each circle of adjustment (by adjustment bolt left hand T 165x6)will change the thickness 0.4-0.5mm.

4.2.3 When machine is operating, oil extruding and residue outlet need be checked

Frequently .Normally, most of oil will flow outward from square rods and several front round plates. Broken cake residue indicates the material is too dry; steam emerging from the cake residue indicates that it is too wet; In any case, water content in the raw material must be adjusted from time to time.

Slag slice emerging indicates too much water content and power-like slag low water content .Loose round plates will cause too much slag flowing outwards. However, adequate water content will cause slag flowing outwards from square rods; little slag from round plates is allowed. In a word, water content affects oil output rate, it needs adjusting properly.

4.3 stopping

4.3.1 Repeatedly move screw forwards and backwards for several times and let all material resided in the chamber goes out and adjust the cake to the possible thinnest, then stop the machine.

4.3.2 When machine stops caused by any accident, power supply must be shut down first, then rotate large pulley manually backwards, let the material return out. Then pull out the shaft and clean it. In the case the shaft could not be pulled out, remove the upper case and loose lock nut, separate round plates and clean them one by one.

5. Maintenance and Assembly/disassembly of Main parts

5.1 Assembly/disassembly of Main parts

5.1.1 Pressing cage (round plates, square rods holder)

Rotate the screw shaft and remove it from the chamber. Loose the lock nut on the outlet end by rotating it counter-clock wise using a 24 mm diameter bar, loose four M14bolts, remove ten M16 bolts which are used to connect upper and lower cases. However, after removing upper case, round plates and square rods holder can be pulled out.

5.1.2 Remove square rods:

After removing the holder, tap the end of one rod and take it out, then others will be easily removed.

5.1.3 Assembly of rods:

Erect the rod holder vertically and make its side with oil grooves locate downwards, better on a wooden plate, then put square rods to touch holders inner wall circumferentially with their grooves downwards again. However, grooves of every two adjacent rods should not be touched. Then insert shins (by a hammer) properly into rods gap to let than firmly touch rods holders inner wall. As a matter of fact, whole inner wall of rods should be smooth.

5.1.4 Assembly of the cage:

Put the groove side of rod the holder to face the machine body, and then insert round plates as per marks on them. Put lock nuts on to contact plates and then mount the upper case. Tighten bolts one by one.

Double Elephant Oil Press

Double Elephant Oil Press